Screwdrivers and bits are essential tools within professional installation, technical assembly, and do it yourself work. In AV related environments where work is carried out with TVs, displays, speakers, racks, mounts, and electronics, there are specific demands for precision, control, and correct fit. Choosing the right screwdriver or bit is crucial to ensure that screws are installed correctly without damaging screw heads, threads, or sensitive components. The most commonly used drive types include slotted, Phillips, Pozidriv, and Torx, which together cover the majority of modern installation tasks. Screwdrivers provide maximum control during manual assembly and adjustment, while bits offer flexibility and speed, especially when used with power drivers and bit holders.

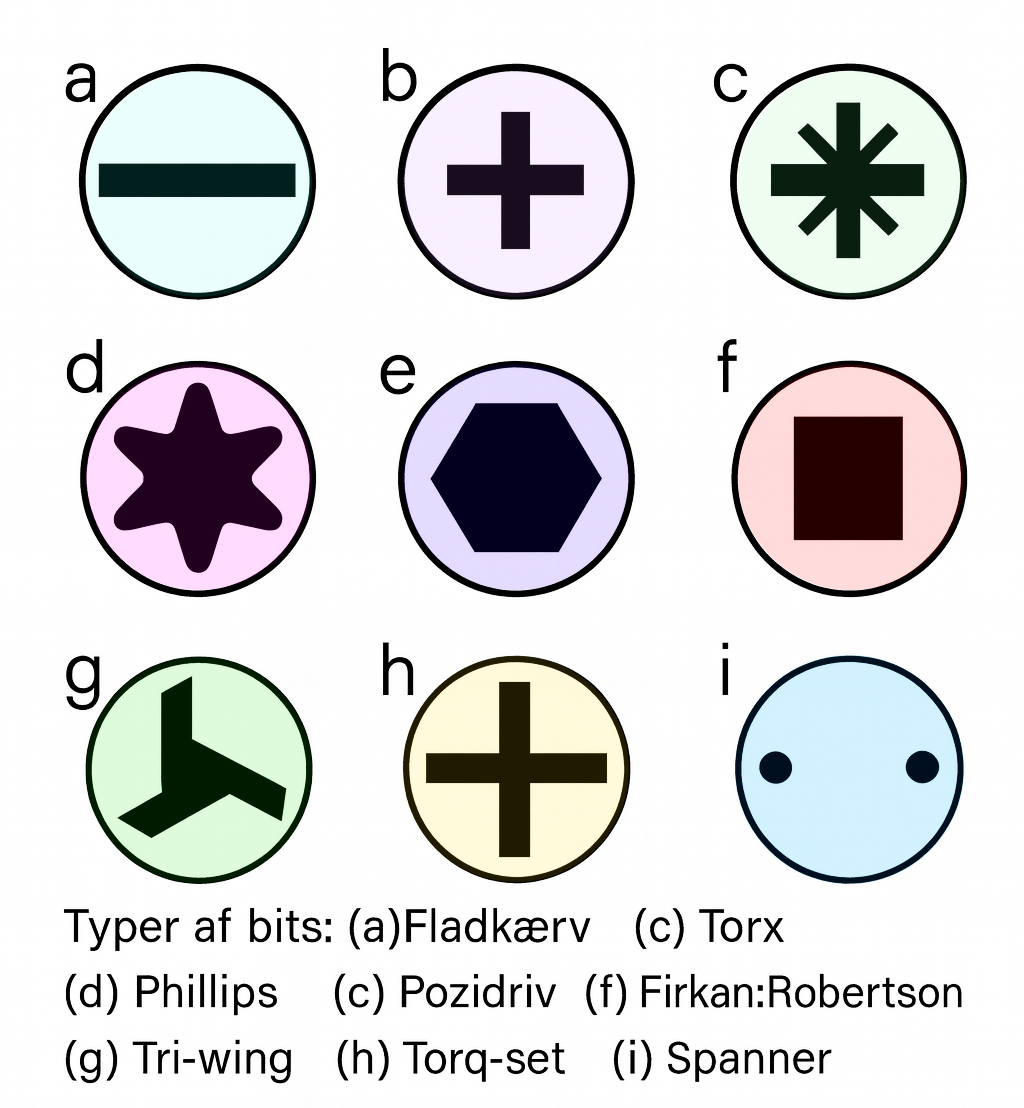

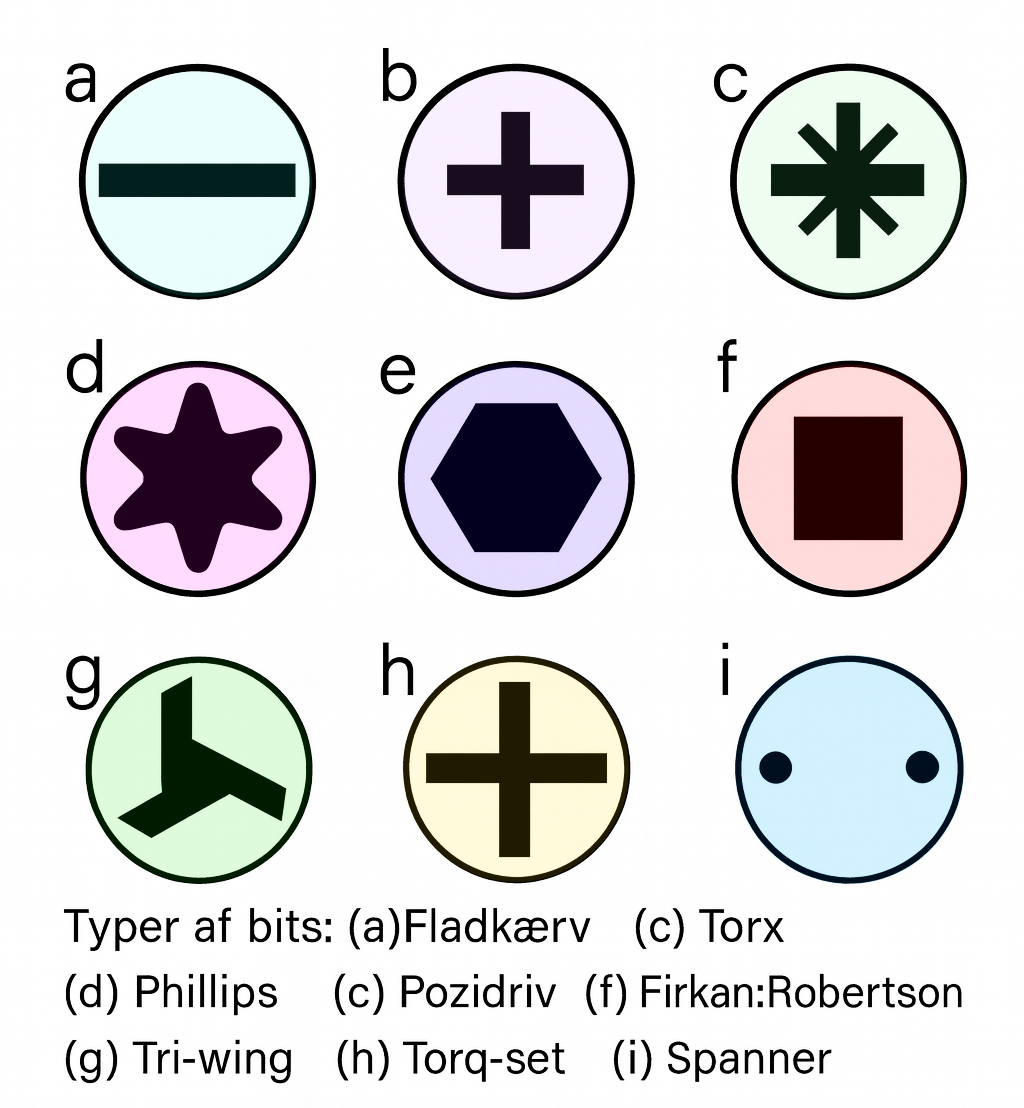

Slotted is a classic drive type that is still used in many situations, for example with terminals, clamps, and adjustable components. Phillips and Pozidriv are among the most widely used cross drive types and are commonly found in mounts, furniture, wall brackets, and general assembly. Although they may look similar, the difference is important, as using the wrong combination can lead to wear and damage to the screw. Torx is now widely used in AV equipment and professional mounting solutions, as the drive shape provides a more secure grip and better torque transfer, reducing the risk of the bit slipping. Knowledge of these drive types makes work faster, more efficient, and more professional.

In addition to the common drive types, a range of specialized bits is used in technical installations and electronics. Hex is often used for mechanical joints, adjustable mounts, and constructions where a discreet and stable grip is required. Square Robertson is known for its excellent fit and is especially seen in construction and certain types of assembly. Tri wing, Torq set, and Spanner are typically used in security screws, industrial equipment, and specialized electronics where there is a requirement that screws cannot be removed with standard tools. These bit types are particularly relevant for service and maintenance of professional AV equipment, where custom solutions are often used.

A well designed bit set brings together the most commonly used bits in various sizes and drive types, making it easy to handle many different tasks without interruptions. In AV installations, it is common to work with multiple types of screws within the same project, for example when mounting TV brackets, racks, cable trays, and speakers. With a wide selection of bits gathered in one place, better overview and a more efficient workflow are achieved. This reduces wasted time, minimizes the risk of errors, and ensures that the right tool is always available. Bit sets are therefore an obvious choice for both professional installers and quality conscious private users.

Bits are often used together with bit holders and power drivers to increase efficiency and reach. Long bit holders provide access to recessed screws behind displays, in racks, and in mounts, while angled bit holders make it possible to work in corners and confined spaces. Magnetic bit holders can hold the screw during installation, which is a clear advantage when working overhead or close to electronics. The combination of screwdrivers, bits, bit sets, and bit holders provides a complete tool solution that covers everything from fine adjustment to heavier assembly tasks.

Screwdrivers and bits are a natural part of the AV Connection range, with a focus on functionality, precision, and professional installation. Whether working with home cinema, commercial installations, meeting rooms, or technical racks, correct tool selection is crucial for a durable and visually clean result. The many different drive types and sizes make it possible to adapt the tool to the task and ensure stable mounting without compromise. With the right tools, better work quality, higher efficiency, and solutions that meet the demands of modern AV installations are achieved.